With the global need to reduce carbon emissions, many industries are heavily investing in electric propulsion. The ability to increase efficiency, reduce the number of moving parts and to utilise zero-carbon electricity generation methods gives electric powertrains a significant advantage for the future.

One of the major challenges in designing electric vehicles is the loss of the internal combustion engine which typically masks transmission noise. Predicting noise using CAE software offers significant benefits, such as avoiding issues from the outset and solving problems without the need for expensive prototyping and testing.

For over 20 years, MASTA has been simplifying powertrain design for engineers. Now, with integrated acoustic analysis, MASTA further simplifies the NVH analysis and optimisation process.

Representation of Sound Intensity in MASTA

NVH Analysis Tools in MASTA

SMT has a well-established record of NVH innovation, offering functionalities such as Advanced Time Stepping Analysis for Modulation, NVH Operating Maps, Inbuilt Electric Motor Analysis as well as Advanced LTCA for calculating gear whine excitations.

These methods have the potential to save engineers significant amounts of time over methods using traditional generic CAE tools.

SMT have also pioneered integrated methods to predict and solve both Spline Rumble and Gear Rattle in MASTA’s Multibody Dynamics module, DRIVA.

|

MASTA is already the go-to tool for NVH analysis for many engineers in the automotive powertrain industry, offering the ability to quickly and efficiently analyse and optimise electrified powertrain NVH performance. MASTA 14 extends this capability to full acoustic analysis.

Dr. Tom Harvey, Software Technical Manager

![]()

“With MASTA 14 you can perform the complete calculation from the excitation at the gears and electric motor right through to microphone sound pressures at any location all in one tool.”

MASTA’s Integrated Full Acoustic Analysis

In previous MASTA releases, there were two options to obtain acoustic results:

- Equivalent Radiated Power (ERP): This fast method estimates the sound power based on the surface velocities of the housing. It provides a single number for the entire housing and is very quick to calculate, making it useful as an optimisation target. It complements the full acoustics calculation and can be used for fast iterations before using the full acoustic simulation to check the detailed impact.

- Export to third-party acoustics packages: Users also have the option to export surface velocities or dynamic boundary conditions in several popular formats. These can be used in third-party software for further analysis. This is something we still support and are actively improving.

For full acoustic analysis in MASTA 14, users have the flexibility to work entirely within MASTA or to export to a range of other packages within their toolchain, such as Ansys Mechanical.

However, industries are demanding a more precise approach, with detailed noise responses at specific locations to correlate with different test setups. This enables the user to see a full picture of the distribution of the powertrain noise with respect to drivers, passengers and pedestrians.

SMT have made the step from frequency domain analysis to acoustic results as easy as possible for the user by heavily automating the setup process.

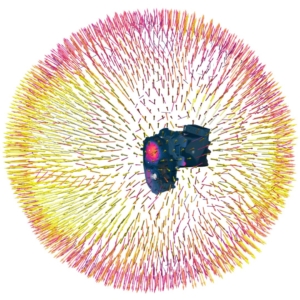

Users can specify their microphone locations either manually or according to the ISO 3745 standard. Following this, the user can move to acoustic setup mode, where MASTA will automatically fill holes in the housing FE geometry. Acoustic Results Surfaces can be easily created and will remain for all variations of FE setup, ensuring reliable and direct comparison of results.

Adding to the ease of this setup, the acoustic analysis is integrated into Harmonic Response mode, utilising the Frequency and Harmonic options from the current Dynamic Response chart.

ISO 3745 Microphone Array

MASTA uses the Wideband Fast Multipole Boundary Element Method, which does not require an acoustic mesh. Instead, it imposes the boundary conditions onto the existing FE mesh, reducing setup time whilst maintaining the accuracy of established methods.

Inkeeping with MASTA’s reputation for an easy and convenient interface, results visualisation can be quickly processed after analysis, eliminating the need to repeat long calculations when switching between results.

Acoustic analysis further expands MASTA’s full electrified powertrain design, analysis and optimisation capabilities, demonstrating SMT’s commitment to powertrain design innovation.

Thank You For Reading

In this blog we have introduced the new acoustics functionality in MASTA 14. If you are interested in more information or a demo, please get in touch.

In MASTA 14, design electrified powertrains, from start to finish.

Related Blogs

High-Speed Ball Bearings – Challenges and Analysis

This article explores and focusses on the behaviour of ball bearings at high speed, but much of it is also relevant to roller bearings.