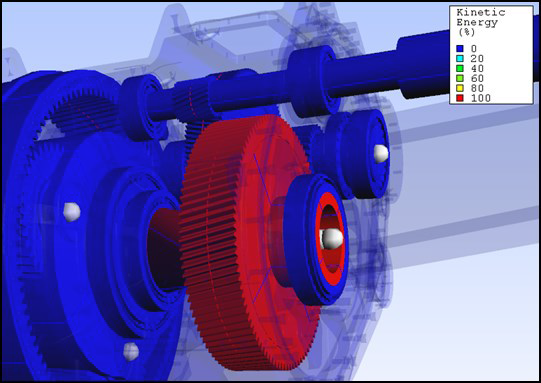

DRIVA – CAE For Flexible Multibody Dynamic Simulation

Simulate dynamic behaviour of drivetrain and the performance of components under variable loading.

DRIVA is a new and innovative solution for the full modelling and dynamic analysis of complete drivetrains.

Based on a full six degrees of freedom flexible multibody dynamics approach, DRIVA is the first solution designed specifically for the analysis of highly time-dependent load conditions of geared mechanical systems.

- Powerful multibody dynamic solver

- Easily generate simulation models from designs and seamlessly update the design model without the need to reimport files

- Rectify problems earlier in the design process